Wedge Wire Screen Terminologies Data

Here we will provide terminologies data for wedge wire screens.

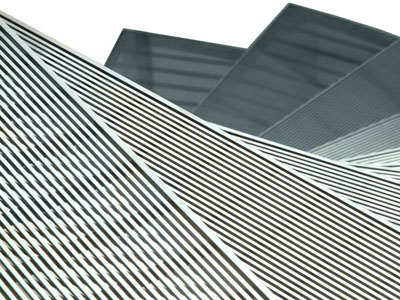

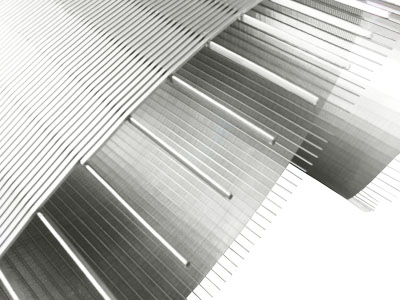

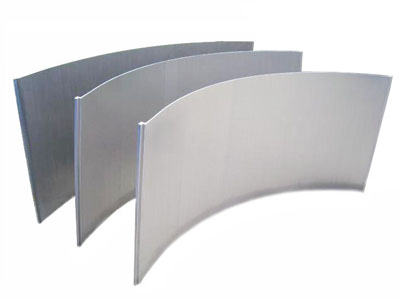

Profile Wire

Profile wire is rolled from a round wire through a series of rolling and annealing operations.

Profile Wire also known as wedge wire, V-wire, Tri-wire or surface profiles. The wedge shape of Profile Wires provides a large opening for material to flow between the wires.

The profile wire sizes please check the data sheet

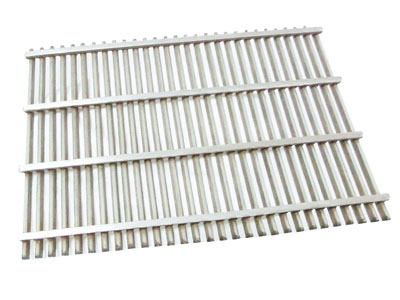

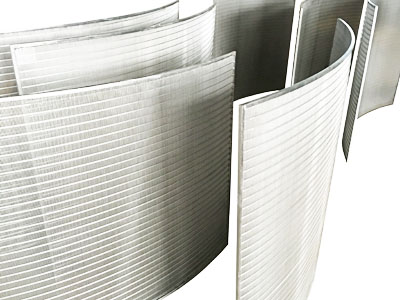

Support Rod

Support wire is rolled from a round wire through a series of rolling and annealing operations. It is also known as support profiles, onto which surface profiles are resistance welded. Support rod includes triangle wire, round bar, flat bar and wedge wire.

The support rod sizes please check the data sheet

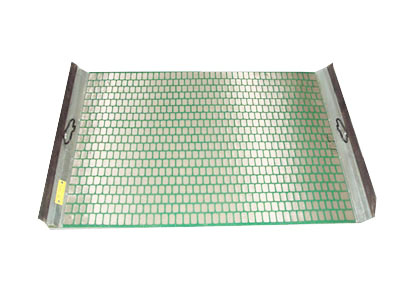

Slot Size

It means the clear distance between any two adjacent profile wires. Slot size is controlled very accurately as it forms the slot through which the filtrate flows.

The Opening Comparison Chart (below) can be used to convert opening units.

Inch | mm | microns |

0.0039 | 0.1 | 100 |

0.0078 | 0.2 | 200 |

0.0118 | 0.3 | 300 |

0.0157 | 0.4 | 400 |

0.0196 | 0.5 | 500 |

0.0236 | 0.6 | 600 |

0.0275 | 0.7 | 700 |

0.0314 | 0.8 | 800 |

0.0393 | 1.0 | 1000 |

0.0590 | 1.5 | 1500 |

0.0787 | 2.0 | 2000 |

0.1181 | 3.0 | 3000 |

0.1574 | 4.0 | 4000 |

0.1968 | 5.0 | 5000 |

0.2362 | 6.0 | 6000 |

0.2755 | 7.0 | 7000 |

0.3149 | 8.0 | 8000 |

0.3543 | 9.0 | 9000 |

0.3937 | 10.0 | 10000 |

Support Rod Distance

It means the clear distance between any two adjacent support rods.

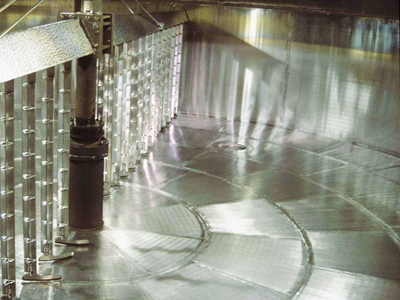

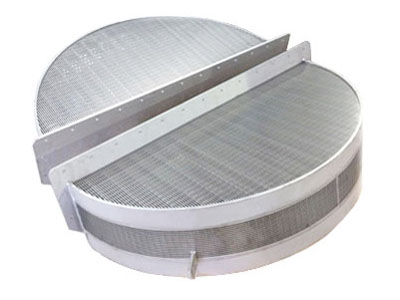

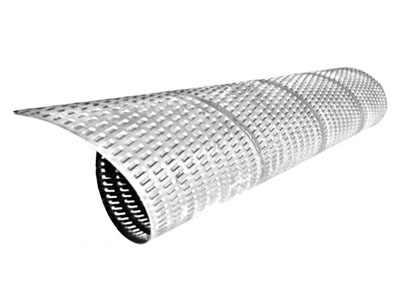

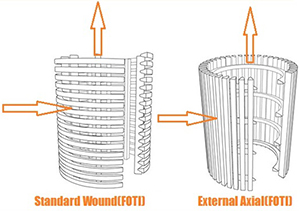

Filtration from outside to inside

FOTI --(filtration from outside to inside) Working surface outside: The triangular shaped slot performing profiles are welded with their wedge side to the inner crossbars. This is the most frequent design which makes the outside working surface smooth,

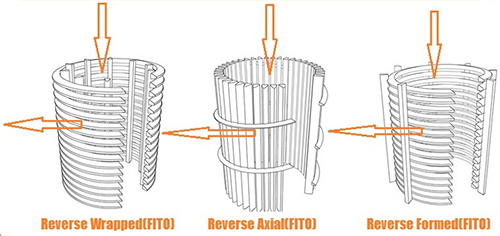

Filtration from inside to outside

FITO-- (filtration from inside to outside) Working surface inside: The triangular shaped slot performing profiles are welded with their flat top side to the inner crossbars. In this design the flat working surface on the inside is interrupted by the position of the crossbars

Wedge Wire Screen Open Area

An important parameter of the wedge wire screen is the open area. Open area OA(%) is the relation of the slot surface to the total screen surface. Open area is calculated according to the following formula:

OA = S/(S+W) x 100 (%)

W– width of the working profile wire

S – slot size

Wedge Wire Screen Weight

The design of each Wedge Wire screen is produced by combining one of the various Wedge Wire profiles with one of the many different size and shaped support rods that are available.

The information below is for estimating weight of the wedge wire screens.

Wedge Wire Screen weight = Wedge Wire weight + Support Rod weight

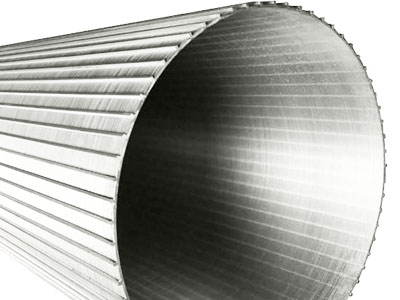

Water well screen technical data

OD (mm) | ID (mm) | Screen Weight (kgs/m) | Max Depth (m) | Tensile Strength (lbs.) |

43.18 | 27.94 | 2.67 | 304.8 | 4,200 |

63.50 | 50.54 | 2.82 | 304.8 | 2,000 |

66.04 | 50.80 | 3.27 | 304.8 | 3,400 |

76.20 | 60.96 | 3.86 | 304.8 | 4,200 |

91.44 | 73.66 | 4.31 | 304.8 | 4,200 |

93.98 | 78.74 | 4.46 | 304.8 | 4,200 |

116.84 | 101.60 | 5.50 | 182.88 | 4,800 |

119.38 | 104.14 | 5.65 | 182.88 | 4,800 |

142.24 | 127.00 | 6.69 | 121.92 | 5,600 |