Applications and Technical Advantages of Wedge Wire Screen in the Food Processing Industry

In the food processing industry, efficient filtration and separation equipment is essential. Wedge Wire Screens are widely used because of their precise slot design and strong structure. They play an important role in many stages of food production, including filtering, separating, drying, screening, and cleaning.

Main Applications of Wedge Wire Screens in Food Processing

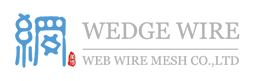

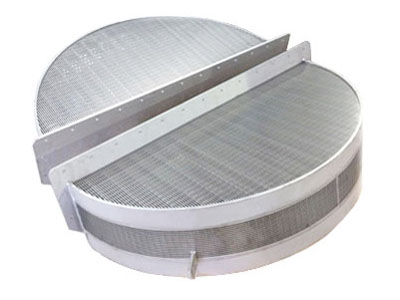

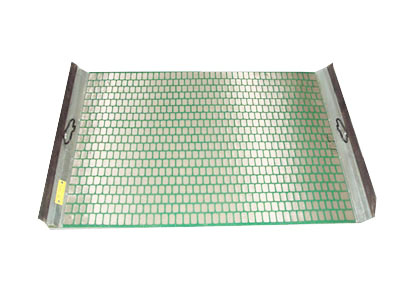

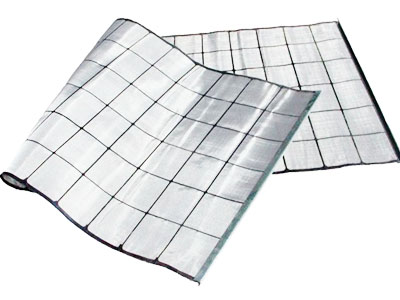

Flat Screen Panels Used for:

Liquid-solid separation

Filtering for beer, juice, and milk production

Screening and sorting food particles

Equipment like vibrating screens and fluidized bed dryers

Flat screen panels are made from food-grade stainless steel. They resist corrosion and easy to clean—making them ideal for fine filtration and pre-treatment of liquid foods.

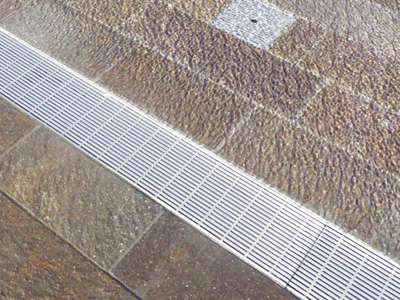

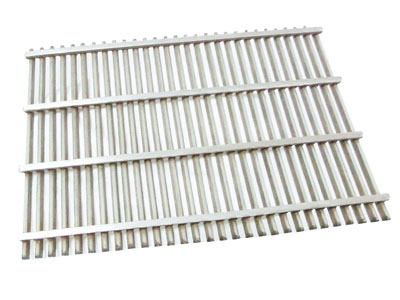

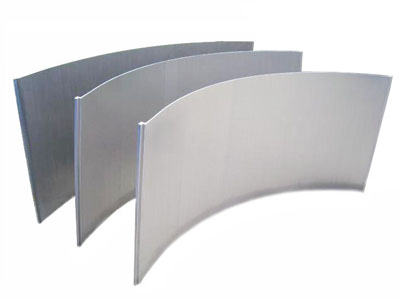

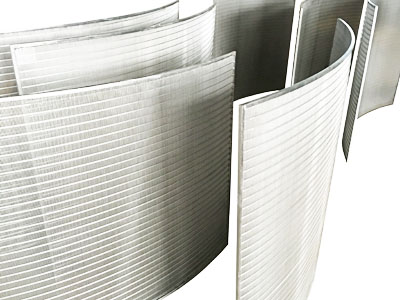

Sieve Bend Screens Used for:

Pre-treatment of sugarcane, corn, starch, etc.

First-stage solid-liquid separation

Washing and sorting raw food materials

These sieve bend screens use the force of flowing liquid and gravity to separate materials. They are compact, which is great for high-volume production lines.

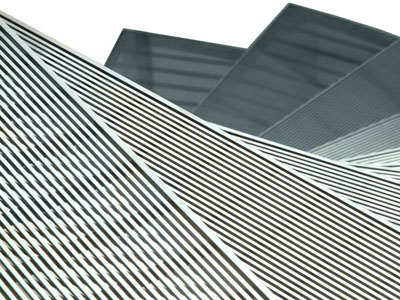

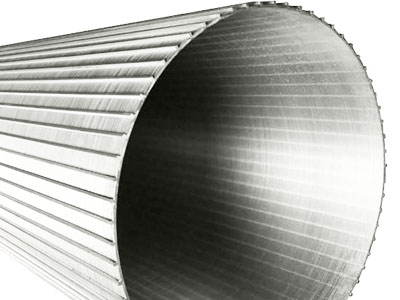

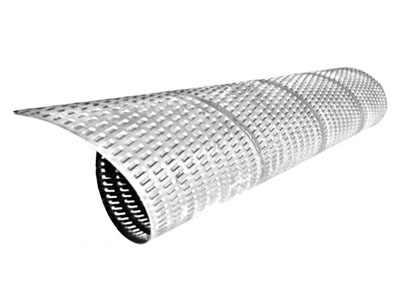

Wedge Wire Cylinders Used for:

Screw press machines (for dewatering fruits, vegetables, or waste)

Continuous filtration and separation

Large-scale processing of fruits, vegetables, and seafood

These cylindrical screens are strong, support high flow rates, and can run for long periods without bending-perfect for large food processing machines.

Wedge Wire Screen Advantages

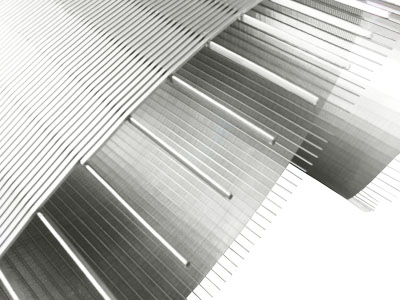

Precise Slot Size

Slot openings can be as small as 0.2 mm, and can be customized to meet different process needs, improving separation efficiency.

Clog-Resistant Design

The V-shaped wire design reduces buildup of debris, ensuring smooth operation.

Food-Grade Material

Made with 304 or 316L stainless steel that meets international food safety standards.

Customizable Structure

Size, shape, and design can be tailored to match specific equipment and production needs.

Corrosion Resistant and Long-Lasting

Resists wear, acids, and alkalis—suitable for harsh food processing environments.

As a professional Wedge Wire Screen manufacturer, we provide high-performance, custom-made screening solutions for the food industry.

Our products are widely used in:

Beverage production (beer, juice, dairy)

Sugar mills, starch factories, corn processing

Vegetable dehydration, food pre-treatment, and solid-liquid separation systems

We offer both standard and custom-made products to ensure the best fit for your equipment and process needs.