The Important Role of Wedge Wire Screens in the Grain Industry

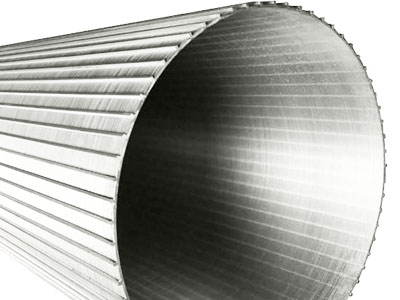

Wedge wire screens play a crucial role in the grain industry, mainly includes two aspects: drying and sieving.

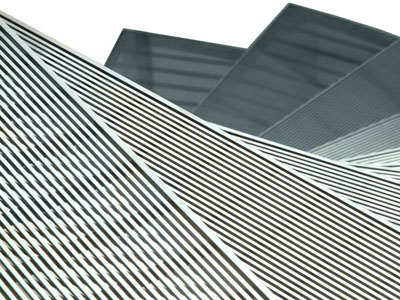

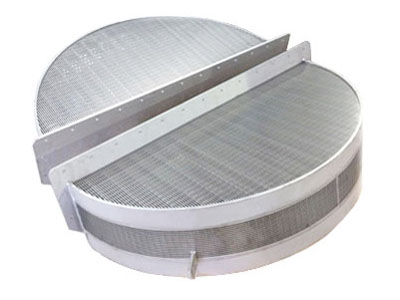

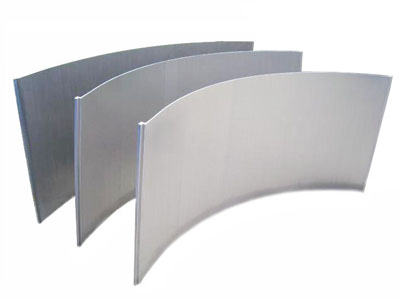

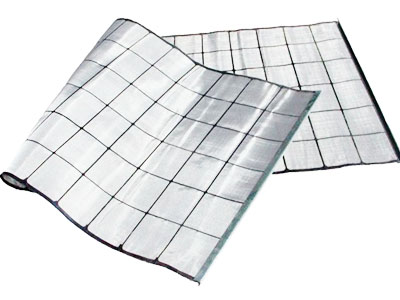

Wedge Wire Screen for Grain Drying

Wedge wire screens provide essential support in the drying process during grain storage. By facilitating continuous airflow, these wedge wire screens enhance ventilation, which helps to quickly remove moisture from the grains and prevent the growth of bacteria in a humid environment. It ensures that the grains are stored under optimal conditions, remaining fresh and extending their life, thus ensuring grain quality. Particularly in seed storage, a high quality ventilation system contributes to higher grain yield and better quality.

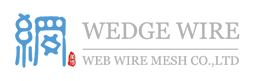

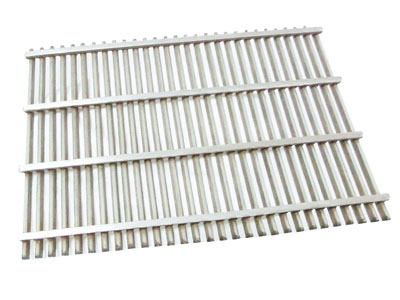

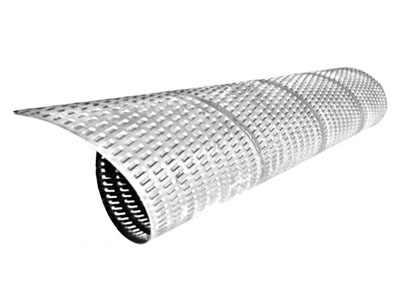

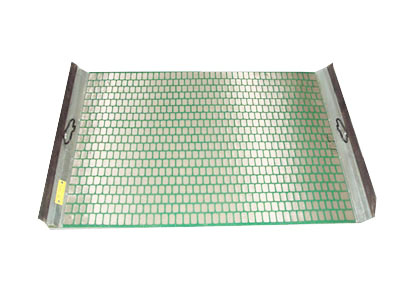

Wedge Wire Screen for Grain Sieving

During grain storage, impurities such as pebbles, particles, and dust may be mixed in, affecting the quality and cleanliness of the grains. Wedge wire screens allow for the adjustment of slot sizes according to the grain's particle size, effectively removing these impurities and ensuring the purity of the grain, which avoids negative impacts on subsequent processing.

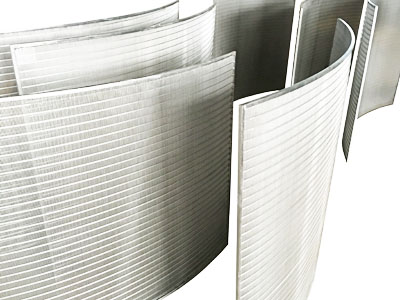

Perforated plates can also be used for drying and sieving purposes, but wedge wire screens have distinct advantages in functionality.

The comparison between wedge wire screen plates and perforated plates

Perforated plates | wedge wire screen plates |

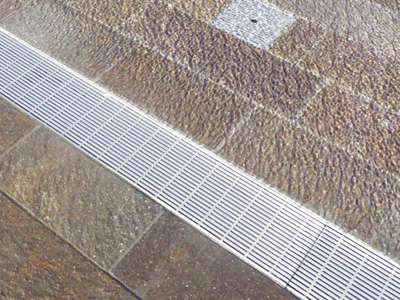

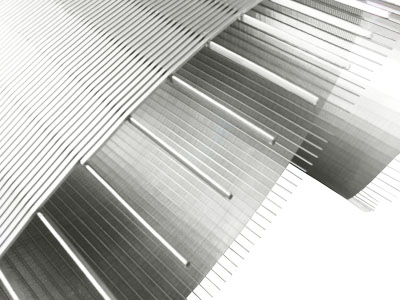

Due to the limitation of perforating strength, the steel plate cannot be too thick, resulting in poor wear resistance and short service life. | Welding at each intersection allows it to withstand high pressures and heavy loads, resulting in excellent wear resistance and service life. |

Limited by the mechanical strength of the perforated plate, the hole spacing cannot be too small, resulting in a low open area | Wide range of slot sizes and high open area. |

When the grain collides with the perforated plate, the rebound force is small and the grain easily blocks the opening. | Unique wedge wire screen construction minimizes clogging |

During the punching process, the perforated plate is subjected to repeated pressure, resulting in poor flatness and affecting the screening effect.

| Has a very smooth filter surface and high flatness

|