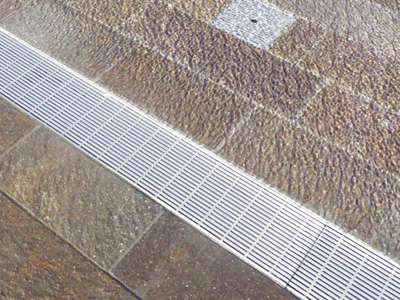

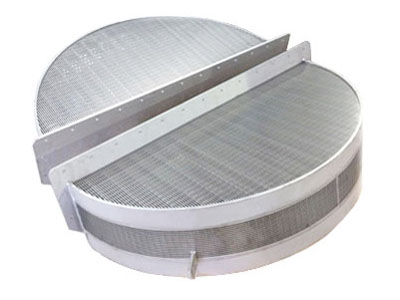

Stainless Steel Wedge Wire Screen Cylinders in the Paper Industry

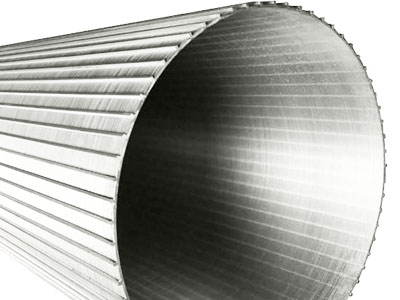

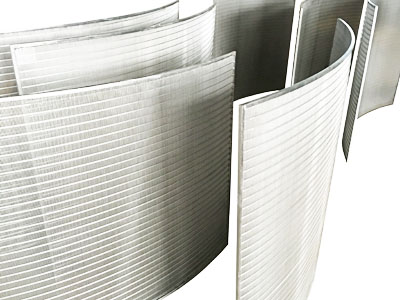

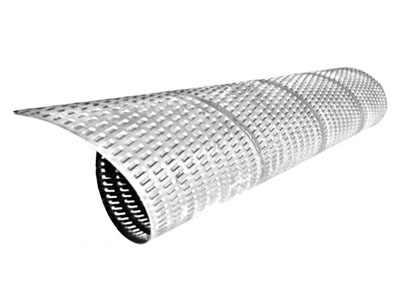

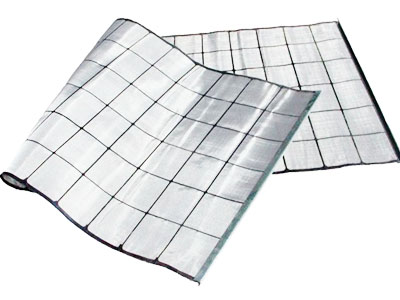

With the rapid development of the paper industry, the demand for pulping equipment has been increasing. Among these, stainless steel wedge wire screen cylinders, as an important component of pulping equipment, have been widely used in the paper industry.

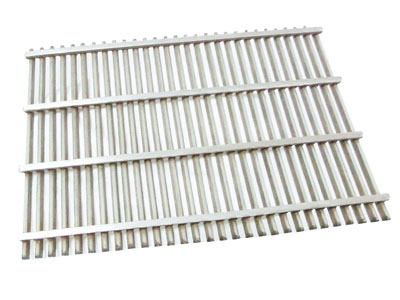

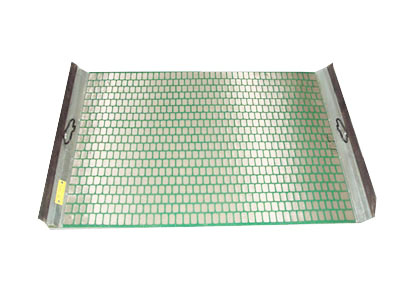

The quality of the wedge wire screen cylinder directly impacts the formation and paper quality, and even determines production efficiency. If the wedge wire screen cylinder is of poor quality, it not only reduces work efficiency but also increases energy consumption, and may even lead to substandard paper quality. High quality stainless steel wedge wire screen cylinders is crucial for improving production efficiency and paper quality.

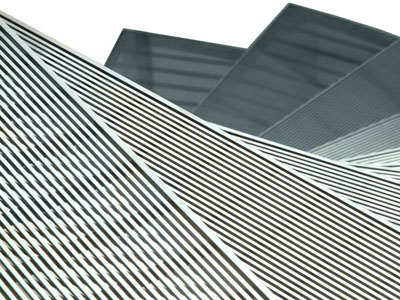

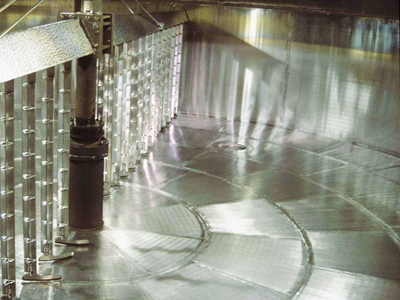

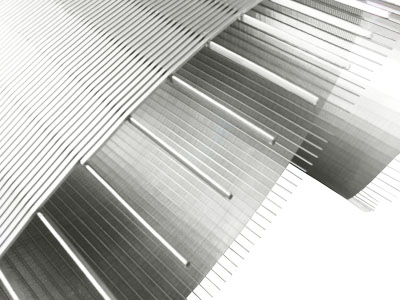

In the pulping process, the main role of the cylinder is to screen the pulp, separating high quality pulp from waste pulp. The high quality pulp enters the paper production line for paper making, while the waste pulp is sent to the waste pulp treatment system. The waste pulp may still contain some amount of good pulp, and the cylinder’s screening ability determines the amount of good pulp in the waste. A high quality wedge wire screen cylinder can effectively reduce the proportion of good pulp in the waste pulp, thereby improving the screening efficiency. Due to the excellent toughness, wear resistance, and moisture resistance of stainless steel, it performs exceptionally well in the screening process, improving screening efficiency.

Moreover, stainless steel wedge wire cylinders have strong sound absorption and noise reduction capabilities, which can reduce the impact of mechanical vibrations and shocks on the equipment, ensuring operational stability. Since the surface of stainless steel is smooth, pulp is less likely to adhere to it, preventing pulp accumulation and clogging of the screen holes, thus ensuring the normal operation of the equipment. With its excellent performance, the stainless steel wedge wire screen cylinder has become a key component in improving pulping efficiency, ensuring paper quality, and maintaining stable equipment operation.