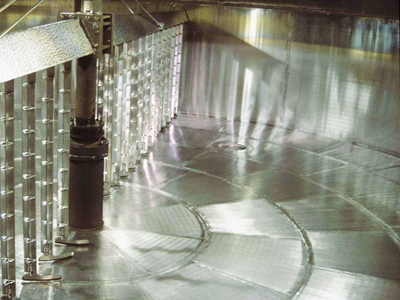

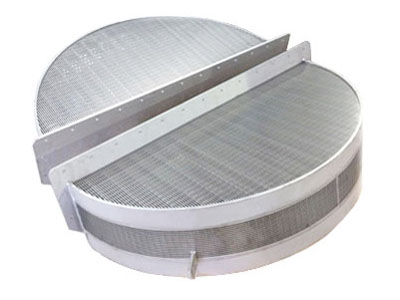

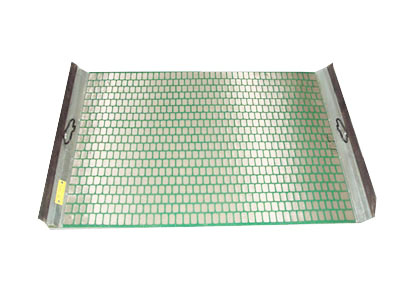

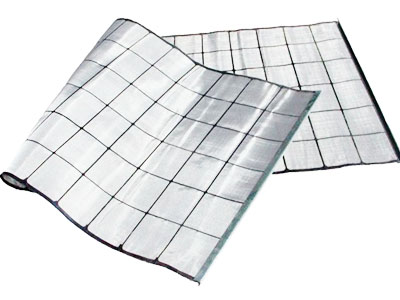

Sieve bend screen used for pulp & paper processing

Woodyard/debarking

Removal of bark, twigs, leaves, dirt and debris, from log flume and wash waters prior to recirculation.

Broke thickening

Effectively dewatering pulp during break conditions on the paper machine without loss of tonnage. Broke can be trim off the paper roll, off the paper machine and from the couch pit.

Mill effluent

Recover loss fiber and improve the clarifier efficiency

Cleaner reject

Dewater rejects from the final stage prior to sewer or disposal to landfill.

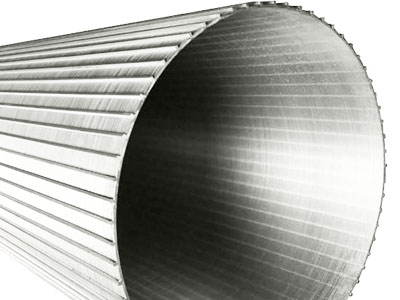

Pulping

Recover fiber from spent digestor liquor (black liquor) to reduce fouling of evaporator tubes, and to reuse the fiber.

Fiber recovery

Tissue, corrugated medium, linerboard, tab card and similar mill effluents contain valuable fiber that can be recovered.

Savell

Placing a screen prior to a flotation system recovers reusable fiber and improves the efficiency of the secondary system.

White water

Recover reuseable short fiber from low consistency flows.

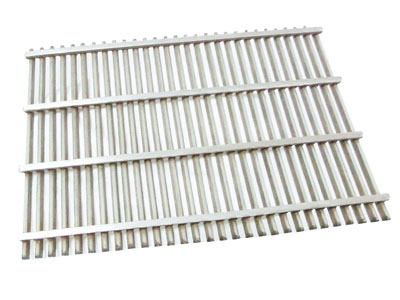

Fractionation

Ash and fines flow through the screen bar openings, with clean fiber coming off the front of the screen. Lower feed consistencies result in higher cleaning efficiencies.