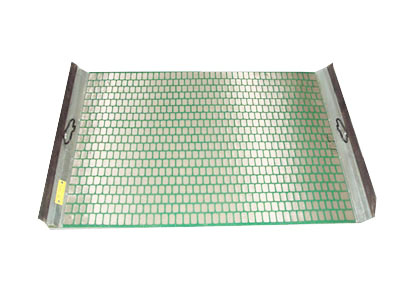

Sieve bend screen for corn wet milling

Corn wet milling separate the corn kernel into various fractions, which allows for the production of food and industrial products including ethanol. The corn wet milling industry was developed in its initial stage with primary purpose of producing starch for use in food and laundry products . In the 19th century wet mills begin producing crystalline dextrose and ethanol. Nowadays , corn refining can produce high-fructose corn syrup, grain alcohol, dry starch, adhesives, coatings and more.

The sieve bend screen involved in corn wet milling processe as below:

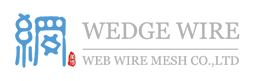

Corn dewatering

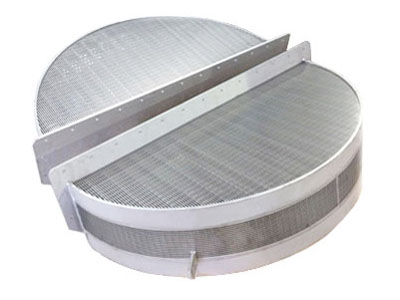

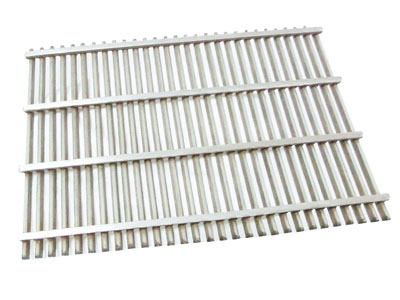

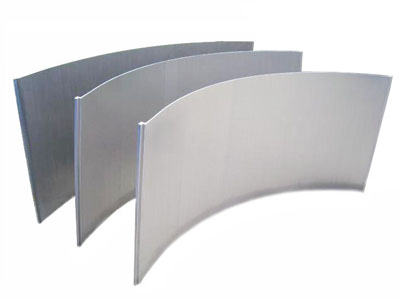

Before the first grind process step, the corn slurry from the destining cyclone is dewatered by a gravity screen. Dewatering the corn slurry prior to milling reduces the hydraulic load on the grind mill and improves the milling efficiency. Gravity screens with 3 mm slot openings are commonly used for corn dewatering.

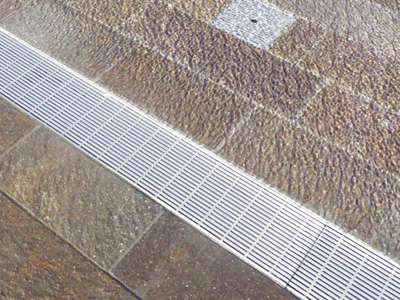

Germ washing processe

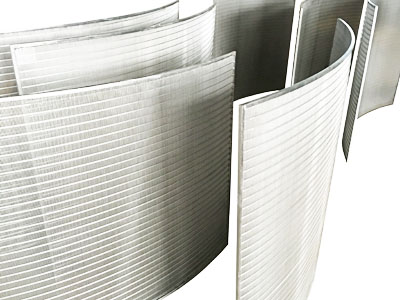

Gravity screens with 1mm screen spacing are common for germ washing screens. Germ washing screens are designed special to accommodate wash headers and stacking so screens can be stacked in the millhouse so the product can cascade from one screen to the next without the need for pumps in between stages.

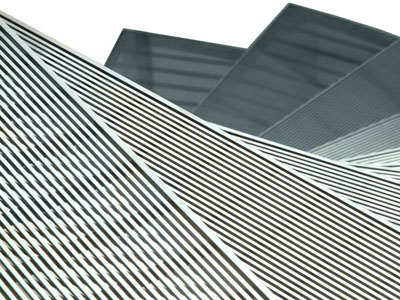

Second grind dewatering screen

Before entering the second grind mill, the slurry from the underflow of the primary germ separation system is dewatered by a gravity screen. Dewatering the corn slurry prior to milling reduces the hydraulic load on the grind mill and improves the milling efficiency. Gravity screens with 1.5 mm slot openings are commonly used for second grind dewatering.

Fiber dewatering

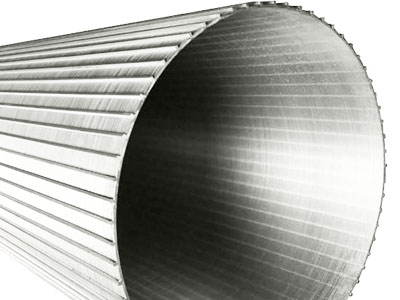

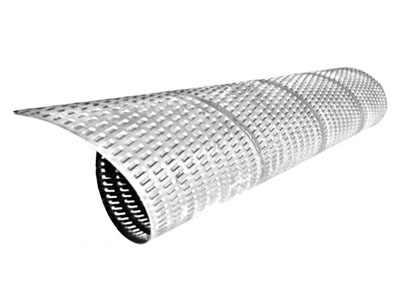

After the fiber washing system, the fiber slurry is dewatered as much as possible with an additional pressure screen. Any water removed from this dewatering screens helps to reduce the dewatering requirements of the down stream fiber press. 120 degree pressure screens with 0.15mm slot openings are commonly used for fiber dewatering