The applications of wedge wire screens in the environmental protection industry

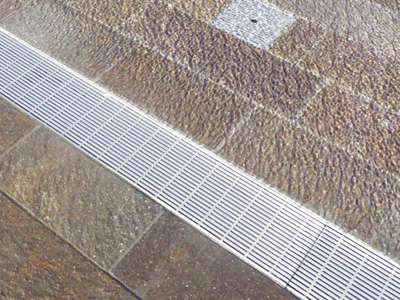

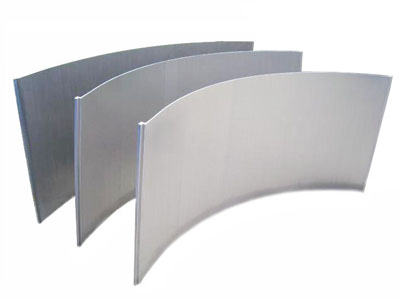

At present, environmental protection has become a global consensus, and every industry is actively exploring green and sustainable development paths. The efficient and precise separation technology is a critical role in the environmental protection industry. Now Wedge wire screen is showing extensive application value with its unique advantages.

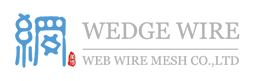

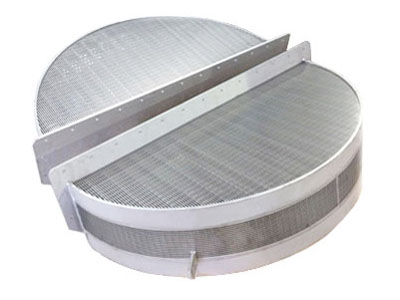

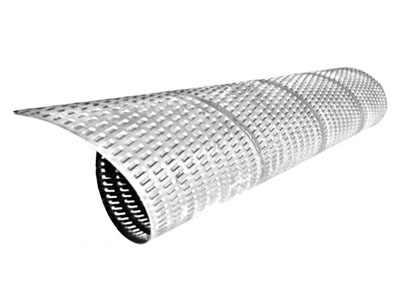

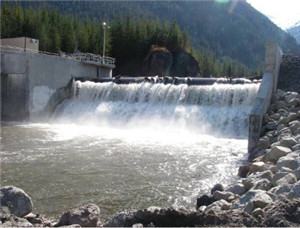

Water Treatment: Wedge wire screens are used in water intake systems to filter out large debris and particulates from raw water before it enters treatment plants. The wedge wire screens prevent damage to pumps and equipment, ensuring a more efficient treatment process.

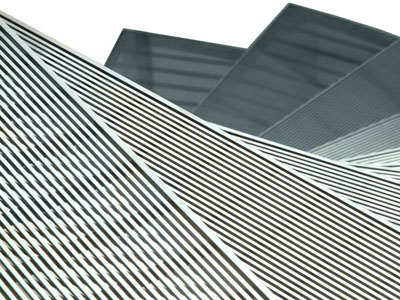

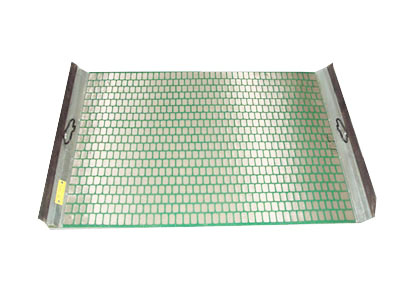

Wastewater Treatment: In wastewater treatment plants, wedge wire screens are used to remove solids from sewage and industrial effluent. They are often used in coarse filtration stages, such as in bar screens, to capture large particles, and also in fine filtration for removing smaller suspended solids.

Fish Protection: Wedge wire screens are used in fish protection systems at water intake points. They have a uniform slot size that ensures fish and other aquatic life are not harmed while allowing water to flow through efficiently.

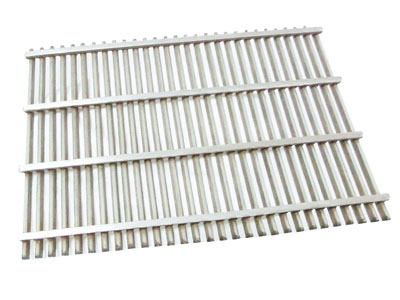

Solid waste treatment: Wedge wire screen also play an important role in the solid waste treatment. Through refined screening, the wedge wire screen can effectively separate recyclables and non-recyclables in solid waste, creating favorable conditions for subsequent resource utilization. For example, during the garbage classification process, wedge wire screens can help screen out recyclable materials such as metals and plastics, improve resource recovery rates, and reduce resource waste.

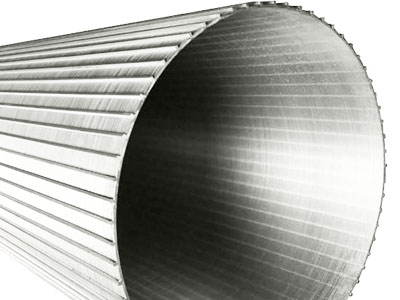

Desalination: In desalination plants, wedge wire screens are used as pre-filters to prevent fouling of reverse osmosis membranes by removing large particles from seawater or brine.